|

By Joshua Coe (Development Engineer for CoePolymer Inc.) May 2010

High performance ‘green’ pavement preservation materials are here to stay as five of the Pacific Northwest’s airports make the switch. Among those to recently install the AROS™ technology based coatings to both primary & auxiliary runways were Oregon State’s Hillsboro, Salem, Corvallis, & Independence Airports with Washington State Packwood Airport completing the list.

With coal tar based coatings now on the Federal government’s list of carcinogenic compounds, state transportation agencies around the nation are now experiencing an immediate need for an alternative long lasting, environmentally safe and fuel resistant coating to preserve their air field pavement assets. A prominent Northwest based engineering firm WH Pacific recognized and anticipated this problem early and began to seek alternative green materials for both Oregon & Washington State Department of Aviation. WH Pacific teamed up with Portland based contractor Roger Langeliers Construction (RLC) to begin evaluation on potential high quality alternative coatings. WH Pacific’s primary requirements for their clients were to find a protective runway coating that met a ‘skid neutral or better’ surface resistance, maintained environment safety, and was cost effective over the long term. The growing team called on the experience of Carbonyte Systems Inc (CSI), to finalize specific mixed designs of CarbonSeal-FR (an AROS™ derived technology) in August 2009. CarbonSeal-FR consists of a base, medium pen asphalt emulsion which is prepared for superior interfacial bond & shear strength through the chemical ‘weaving’ of polymer grafted & dissolved ground tire rubber (GTR) to make a superior rubberized asphalt pavement coating. Daytime applications of CarbonSeal-FR involve a 20% cut by volume but in order to facilitate curing for Hillsboro’s nighttime application, the CarbonSeal-FR would only be cut to 15%.

On the early evening of September 3rd crews began to capture and prep Hillsboro’s primary runway with weather forecasted as partly cloudy and air/pavement temperatures in the low 60’s and falling. With storage tanks and drivers on stand-by and Hillsboro’s secondary runway live with air traffic, crews began cracksealing operations at 7pm. By 10pm RLC’s project manager Jim Cross and his spray crews were poised to enter the runway and begin the first spray application of the CarbonSeal-FR. Surface temperatures were well into the 50’s as trailer mounted light towers illuminated the way for the spray buggies while they laid down 10 foot swaths of material totaling 0.25gal/yd². The first section of the primary runway, described as the main touch down area before the intersecting runways, was completed with a two coat application by 3am Friday. At around 5am, just two hours after the initial application, temperatures had fallen into the low 50’s and an unexpected and isolated rain cell passed directly over Hillsboro’s runway. The airport engineers along with RLC’s crews were in disbelief as the only rain cell in the area chose a direct path over the airport and proceeded to completely wet out the surface before the coating had yet fully cured. Pulses were running high as everyone stood in the morning darkness enduring the unpredictable rains of the Northwest and wondered what would happen next. Friday morning’s first light came at 7am and project leaders were eager to get a good look and see how well the coating held up to the early morning rain assault. Everyone was relieved to see that the material appeared to be unaffected and had properly coalesced despite the rain. At 9am airport inspectors had arrived to walk the affected area and were very impressed to find that the coating had not only held up but was ready for touchdown traffic! RLC crews, lead by supervisor Kenny Wood, got to work re-staging for the remaining sections of the primary runway and were ready to go by 11am. The weather had broken up and the sun was shining through as air temperatures rose into the 70’s and surface temperatures were averaging 115F. RLC had picked up the pace and had split off a second team that would be poised to capture the live runway intersection at 12pm. The application window for the runway intersection would be short as RLC crews were only allotted one hour to capture and apply two coatings before air traffic resumed. With airport managers on site, the clock struck twelve and the green light was given as the well orchestrated blitz on the intersection began. By 12:50pm the crew pulled the last cone and everyone breathed a sigh of relief as the airfield operations manager took a final look. With radios in hand everyone stood on the sideline to witness the first turbo prop aircraft lift off at 1:15pm without issue. Airport officials continued to monitor air traffic first hand and any remaining reservations were quickly replaced by notable confidence in the technology. Crews resumed spray application on the remaining section of Hillsboro’s primary runway, completed the final pass, and re-opened the runway at 7pm Friday evening. Heavy rains were forecast for late Friday evening and on into Saturday morning and the freshly sealed runway was faced with a true Northwest rain storm within the first 24 hrs of application. Later inspection revealed that the CarbonSeal-FR coating had held its ground without a mark on its armor. With the Northwest rain season gearing back up and the winter just around the corner we would have to wait until spring to revisit just how well the coating held up. In March 2010 we were given the opportunity by the Port of Portland to walk the Hillsboro airport runway and see first hand how the CarbonSeal-FR coating was holding up during its seven months of service. As you can see in the photo below, after a long Northwest winter, the coating still looks as new as the day it was applied. (click on images to enlarge) Salem

The primary challenge when sealing this type of runway, and a main concern for ODA, is achieving a uniform coating on the pavement without filling in the breaking grooves. To make this happen, the application rate would either have to be extremely low (thus requiring several coats) or the material would need to display a gelatinous behavior that allows the material to ‘stand up’ on the pavement during heavier spread rate applications. With high air traffic count throughout the day, McNary Airfield doesn’t have the luxury to shut down for extended periods while numerous ‘fly coats’ are applied. ODA needed an expedited application of a tough material that would stand up on the pavement and give McNary runways the required protection while maintaining the surface breaking resistance. They needed CarbonSeal-FR.

(Before and After shot of McNary runway gooves) In September 2009 CarbonSeal-FR touched down as the multi-runway installation got underway with the experienced RLC behind the stick. The weather conditions were sunny and clear with temperatures into the 70’s. Due to the unusually high concern about maintaining the integrity of the breaking grooves ODA officials and Port of Portland Engineers were on hand to closely watch the completion of the first runway installation. Airport officials were pleased and expectations were met as the CarbonSeal-FR uniformly coated the runway grooves without flooding the individual channels.

The 1.35 million ft² installation on McNary Airfield was completed in four days by RLC with support from Salem airport operations manager Tom Franklin, WH Pacific aviation engineer James Kirby, CSI, and Prime Plex. The collective efforts from all who were involved contributed to the success of this project and it will be the unparalleled & proven strengths of the AROS™ technology that will help to sustain this success over time. Additional information & technical data on CarbonSeal-FR and other AROS™ based technologies can be found at http://www.coepolymer.com/Technology.html

(Click on before & after photos to enlarge) McNary Airfield August 2009 McNary Airfield March 2010

|

COE Polymer, Inc. All Right Reserved © 2009-2010

webmaster@coepolymer.com Web Master

Hillsboro

Airport, located in the western suburbs of Portland, is Oregon’s largest

& busiest general aviation airport handling over 250,000 annual flights.

The 6,600 ft long (150 ft wide) primary runway is host to many local corporations such as Nike & Intel and plays an integral role in

offsetting air traffic in & out of Portland International Airport. High

air traffic demand, coupled with the Northwest’s four season climate and

annual precipitation of 40 inches, requires the highest performance in

runway protection.

Hillsboro

Airport, located in the western suburbs of Portland, is Oregon’s largest

& busiest general aviation airport handling over 250,000 annual flights.

The 6,600 ft long (150 ft wide) primary runway is host to many local corporations such as Nike & Intel and plays an integral role in

offsetting air traffic in & out of Portland International Airport. High

air traffic demand, coupled with the Northwest’s four season climate and

annual precipitation of 40 inches, requires the highest performance in

runway protection.  Extensive

evaluation of the CarbonSeal-FR was conducted by the Port of Portland

which included full scale field testing of

skid resistance, utilizing a continuous slip friction tester. This type

of runway measurement system meets all FAA and ICAO specifications for

friction measuring devices and demonstrated that the CarbonSeal-FR

coatings were skid positive, achieving the ‘skid neutral or better’

requirement. Oregon Dept of Aviation (ODA) also spent time validating

CarbonSeal-FR’s ability to be immediately striped upon curing,

allowing same day striping operations. Previous systems used by ODA

required several days of curing to pass before striping could safely

commence. Upon approval and cooperation with the region’s late season

weather patterns, the near one million square foot runway job was set to

kick off during the first week of September.

Extensive

evaluation of the CarbonSeal-FR was conducted by the Port of Portland

which included full scale field testing of

skid resistance, utilizing a continuous slip friction tester. This type

of runway measurement system meets all FAA and ICAO specifications for

friction measuring devices and demonstrated that the CarbonSeal-FR

coatings were skid positive, achieving the ‘skid neutral or better’

requirement. Oregon Dept of Aviation (ODA) also spent time validating

CarbonSeal-FR’s ability to be immediately striped upon curing,

allowing same day striping operations. Previous systems used by ODA

required several days of curing to pass before striping could safely

commence. Upon approval and cooperation with the region’s late season

weather patterns, the near one million square foot runway job was set to

kick off during the first week of September.

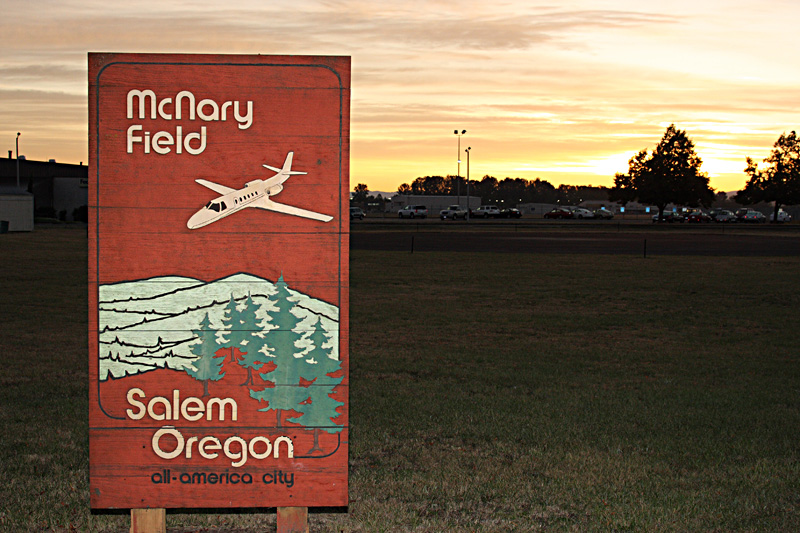

McNary

Airfield, located in Oregon’s capital city of Salem, is home to the

Oregon Department of Aviation (ODA) and boasts two general aviation

runways (5,811ft and 5,145ft) that support over 50,000 aircraft

operations annually. McNary’s runways are unique in their design and

pose a special kind of challenge for any pavement preservation

technology. Both primary and secondary runways contain ¼” x ¼” breaking

grooves that shorten stopping distances and allow McNary Airfield the

ability to service larger jet aircraft.

McNary

Airfield, located in Oregon’s capital city of Salem, is home to the

Oregon Department of Aviation (ODA) and boasts two general aviation

runways (5,811ft and 5,145ft) that support over 50,000 aircraft

operations annually. McNary’s runways are unique in their design and

pose a special kind of challenge for any pavement preservation

technology. Both primary and secondary runways contain ¼” x ¼” breaking

grooves that shorten stopping distances and allow McNary Airfield the

ability to service larger jet aircraft.