|

Transportation Infrastructure Construction Technique(s) & Environmental Impact Review February 27, 2009

Q. Which needs are of the highest priority for the U.S. transportation infrastructure?

A. The United States highway and road infrastructure has an urgent requirement for a paradigm shift in materials technology that will both far outlast current road materials technology as well as fit within incurred state and federal budgets. As a part of the recent stimulus package signed by the Obama Administration, the American Recovery & Reinvestment Act of 2009 will provide $64.1 billion for transportation infrastructure investment. Responsible & creative spending of these stimulus dollars are necessary in order to develop and implement technologies that will help to lower life-cycle costs, dependence on foreign resource, and reduce America’s carbon footprint. With respect to the need to reduce our carbon footprint, and in coordination with the above stated primary need, there is a secondary need to reduce and reuse the growing stockpile of scrap tires in the United States. With the annual addition of over 290 million scrap tires to America’s already stockpiled 250 million scrap tires the commitment to recycling this valuable resource is both necessary and our responsibility[7]. Q. How large is the current U.S. transportation infrastructure?

A. Today there are over 7 million miles of road and highways that play a vital role in sustaining America’s economy. With current road pavement technologies needing to undergo major renovation/replacement every 10-20 yrs the transportation infrastructure just isn’t surviving within the available state & federal budgets.

Q. What is the most promising alternative to standard pavement technology?

A. "Since the 1960s an alternative paving technology utilizing crumb rubber modifiers (CRM) has been used in highway applications. Numerous technologies have been evaluated, with varying degrees of success. Asphalt rubber (AR) [utilizes crumb rubber modifiers] which has the longest history of use in highway applications, must meet the requirements given in ASTM D-6114 “Standard Specification for Asphalt-Rubber Binder” including the following:

"From 1974 until 1989, approximately 660 miles of state highways were built using a SAM or SAMI application of AR. During the last 20 years the ADOT and FHWA have sponsored numerous research studies on an alternative asphalt rubber paving technology which resulted in 42 research reports being published, thus greatly increasing the state-of-the-knowledge concerning AR"[3]. By way of example, AZ currently has over 3000 miles of AR paved highways. IT IS A CERTAINTY THAT AR TECHNOLOGY WILL HAVE AN ENORMOUS IMPACT ON THE U.S. TRANSPORTATION INFRASTRUCTURE

Q. Is AR technology cost effective?

A. "A two-inch thick rubberized asphalt concrete overlay can potentially save as much as $50,000 per lane mile when compared to a four-inch thick conventional asphalt overlay"[2]. "A life-cycle cost analysis (LCCA) was conducted and is based on information provided by agencies. The results of the analysis warranted the following conclusions:

- Fore the scenarios evaluated, asphalt rubber is a cost effective alternate for many highway pavement applications. - When variability is considered in the inputs (cost, expected life, etc.), the asphalt rubber alternates would be the best choice in most of the applications considered. - Asphalt rubber was not cost effective in all applications. LCCA allows one to determine when and where AR will be cost effective. The results of LCCA are highly dependent on the input variables. Many times these inputs are only best estimates. Every effort is needed to obtain accurate estimates of the average value and expected variability for each input variable. Further, the cost effectiveness of AR is dependent in many of the cases on the ability to reduce thickness when using AR. Without a reduction in thickness, or longer lives for equal thicknesses, the AR alternates would not be cost effective.[1] Results from the Arizona DOT indicate that the AR alternate to be cost effective in all applications. Caltrans survey results indicate that all applications except multiple AR chip scenarios were cost effective over 70% of the time. The results from Texas DOT showed that three of the eight comparisons proved not to be cost effective. (stressed that results are based and are highly dependent upon input values collected from interviews and that different outcomes would result if parameters were changed)"[1].

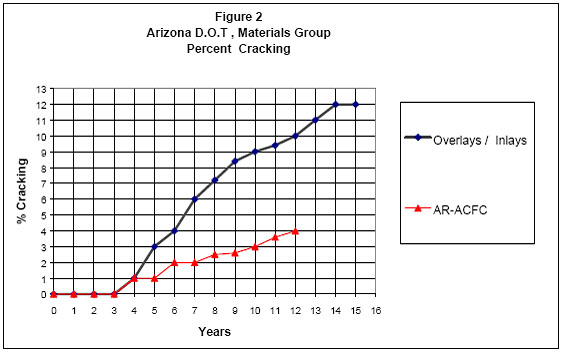

Q. Do AR roads really last longer? A. "In 1988, a 25 mm (one inch) layer of an open-graded asphalt rubber asphalt concrete friction course commonly referred to as AR-ACFC was placed on several miles of Interstate 19, south of Tucson. The gradation of this mix is shown on Figure 1. This AR-ACFC mix, containing 10.0 percent asphalt rubber by weight of the mix as the binder (note: dilutant is no longer used), was placed on top of a plain jointed concrete pavement. Table 1 shows the mix design equation used to determine the AR-ACFC binder content. All AR mixes for ADOT projects are designed in the Materials Central Laboratory. Since 1988, no cracks reflected through until 1996, when only a few transverse cracks appeared over the concrete joints. In 1999 District Maintenance reviewed this project and concluded that as before no maintenance was needed and amazingly to date twelve years later no maintenance has been performed on this section. From this first project, dozens of projects have been successfully built with asphalt rubber as the binder[3]. (additional information from referenced article) The AR contains 20 percent ground tire crumb rubber by weight of the asphalt content. These projects were built with the expressed purpose of controlling reflective cracks with a very thin layer of very elastic material. To date, all projects have performed as expected. As a further extension of this work, a structural overlay called a gap graded AR-AC (Figure 1) was designed and built in 1990 on Interstate 40 near Flagstaff, using AR as the asphaltic concrete binder (5 & 7). This project also contained numerous Strategic Highway Research Program (SHRP) test sections as well as ADOT test sections. The purpose of the project was to overlay a severely cracked and failed concrete pavement. As of the most recent objective crack mapping review in May 1999, the asphalt rubber sections built as the top portion (overlay top 50 mm (two inches) AR-AC, 12.5 mm (half inch) AR-ACFC) have the least percentage of reflective cracks. Indeed the percent cracking of the AR section is less than one third of the 100 mm (four inch) conventional overlay and less than one half the 200 mm (eight inch) overlay. The AR overlay project built in 1990 as of today, ten years after construction, still has no cracking[3]. The AR-ACFC continues to provide a smooth riding, virtually crack free, good skid resistant, quiet and virtually maintenance free surface [after the 12 year study]…. The use of AR on this I-40 project alone conservatively saved at least $18 million dollars and about four years of construction traffic disruption. Attached pictures of I-40 before overlay (Illustration #2) and pictures taken in November 1997 (Illustration #3), clearly show the long term benefit of the use of AR on this project. In 1998 additional comparative photos were taken from a higher vantage point and also clearly show the reduction in reflective cracking due to AR (Illustration #4)[3]. Figure 2 shows a comparison of the average percent cracking for conventional overlay/inlay projects and those projects built with an AR-ACFC"[3].

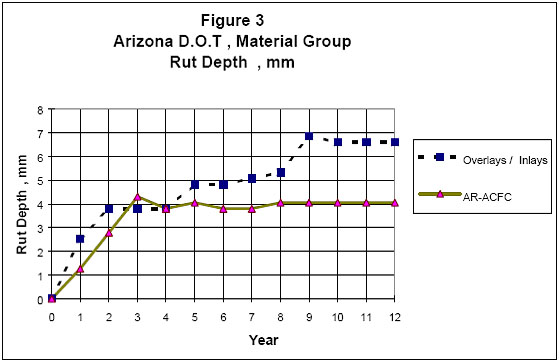

Figure 3 shows the average rutting performance which has been surprisingly better than expected[3].

Q. How 'green' is AR road technology? A. "Asphalt rubber roads that meet the ASTM standard of minimum 15% scrap tire rubber utilize an average of over 2,000 scrap tires per lane mile (for a two inch overlay). This means that for a one-mile section of a four-lane highway, over 8,000 scrap tires are used"[2]. "In addition, vehicle tire wear contributes to atmospheric particulate matter (PM) and is regulated by the U.S. Environmental Protection Agency because PM has been shown to affect human health. A study found that emission rates of tire wear per kilometer driven on PCC (Portland Concrete Cement) road surfaces were 1.4 to 2 times higher than emission rates of tire wear on ARFC (Asphalt Rubber Friction Course) road surfaces"[5]. "The good news is that due to the passage of State Assembly Bill 1843 in 2000 and the establishment of the Tire Recycling Management Act, the California Integrated Waste Management Board (CIWMB) is leading a revitalized effort to recycle tire material. CIWMB provides assistance by promoting the use of rubberized asphalt concrete, commonly known as RAC and affectionately referred to as "rubber roads." Rubberized asphalt concrete, a paving product made from aggregates, asphalt cement and reclaimed tire rubber. The city of Thousand Oaks knows firsthand the benefits of using RAC. The city has been using the product since 1992. To date, Thousand Oaks has used rubber from 1.3 million discarded tires to resurface hundreds of miles of surface streets. The city found that the improvements-increased skid resistance, reduced road noise, improved riding qualities and imperviousness to water-have made the use of RAC cost effective and more desirable than traditional asphalt concrete. Thousand Oaks is not the only city that has used RAC. The CIWMB awarded more than 60 grants totaling $4.2 million between January and April of this year alone. Many of these grants help first-time or limited-RAC users, including San Clemente, Fremont, Rancho Cordova, Brea, San Fernando, Galt, Ripon and Nevada City, to name just a few. Individuals, businesses, local governments, universities, school districts, park districts, and qualified California Indian tribes are also eligible to apply for the grants."[2]

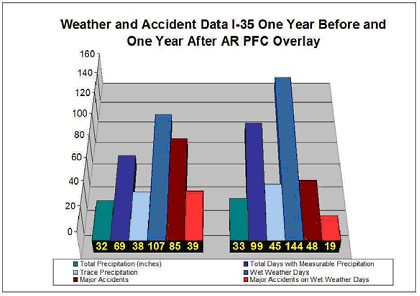

Q. Are roads safer using AR technology? A. "Asphalt rubber roads provide improved traction and wet weather visibility which has proven to reduce the number of highway accidents. A study was conducted to contrast the number of wet weather accidents before and after an AR friction course overlay. The results showed that the number of major accidents overall had decreased from 85 to 48 and wet weather major accidents dropped from 39 to 19"[4]. A 51% reduction in major accidents!

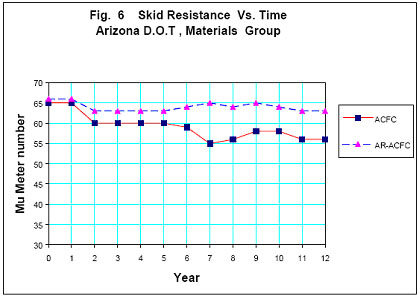

The figure below shows the Mu Meter skid resistance versus time; it shows that the ARACFC has a slightly higher skid resistance over time than the conventional ACFC[3].

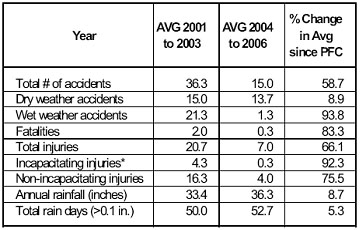

Another road in Texas had an unusually high number of accidents and fatalities. So the TexDOT provided an emergency contract to place a PFC overlay on the dense graded asphalt surface on Farm to Market Road FM 1341. A tremendous improvement was noted after the overlay. Although the dry weather accidents were not as significantly affected, some improvement was made with reduction of nearly nine accidents on average each year. What is most important is the reduction in accidents in wet weather. On this project the average number of wet accidents dropped over 93%, from an average of 21.3/year to 1.3/year, total injuries dropped over 66% from 20.7 to 7.0.[4]

A striking “statistic” is the reduction of accidents resulting in fatalities from 6 in the three years leading up to the surface improvement to 1 in the three years following the improvement. An 83% reduction in fatalities resulted from a surface improvement[4].

Q. Do AR roads reduce noise pollution?

A. "With regard to traffic noise, an Arizona Transportation Research Center study (6) printed in 1996, indicated that an AR-ACFC can lower the noise by as much as 5.7 decibels….Therefore, the AR-ACFC overlay appears to be capable of noticeably reducing roadside noise levels in certain situations.”[3] "Research has as shown that noise can be reduced as much as 85 percent using an open graded rubberized friction course"[2].

Q. Can AR roads reduce vehicle operating costs?

A. "AR PFC provided an excellent ride improvement, 61%, as is seen in the IRI chart. A-R overlays will typically cut the roughness in half every time"[4]. This translates to lower rolling friction and ultimately lower vehicle operating costs with improved tire wear of up to 50% and an increase in fuel efficiency of almost 5%[6].

In Summary, the use of AR in highway pavement establishes that:

Q. What emerging improvements are there for AR road technology?

A1. Inasmuch as asphalt rubber pavement has proven to be the most superior of all pavement construction materials, an advanced process technique which further advances the effectiveness of asphalt rubber is the P2GTR™ (PRIME Permutated Ground Tire Rubber) process.

Through continuous ARB evaluation it has been discovered that when smaller than 140 mesh (75-100 microns) rubber particles are used, rather than the conventional 20-40 mesh (850-600 microns), that fatigue resistance is increased by a full factor resulting in predicted pavement life of 30 yrs or more. The smaller ARB particle improves fatigue resistance for several reasons:

The current method of rubber particle size reduction, to the optimal 75-100 micron range, utilizes expensive cryogenic process steps with production costs of $1-2 per pound making it a non-viable option for ARB pavement systems. The P2GTR™ innovation has shown the greatest promise in attempting to reduce the rubber particle size with a ca 50% reduction in production cost making the process a viable option. In addition to the cheaper production costs, the P2GTR™ process produces a fine rubber particle with highly reactive sites that allow the particle to be re-crosslinked into the ARB adhesive; resulting in improved elasticity under cold weather conditions.

A2. Now ARB is user friendly

ARB is now available as an emulsion and the technology is called AROS™ (Asphalt Rubber Oxidation Shield). The AROS™ innovation, which has a patent pending, begins as a base thermoplastic adhesive which is prepared in accordance with ASTM D6114-97 wherein a minimum of 15%, very fine crumb rubber (80-600 mesh) is blended into and reacted with hot asphalt. Thereafter the Asphalt Rubber is compounded and emulsified into a smooth, stable, waterborne adhesive. AROS™ can be formulated as a coating, sealant and/or adhesive which will cure quickly to a non-tracking, water resistant binder or surfacing element with superior resistance to; oxidative hardening, weather or mechanical wear. It may also be formulated to cure at non-traditional winter temperatures down to 40F and; at night. AROS™ system performance highlights:

Reference:

|

COE Polymer, Inc. All Right Reserved © 2009-2010

webmaster@coepolymer.com Web Master